Wedge Wire Screen for Coanda Hydro Water Intake

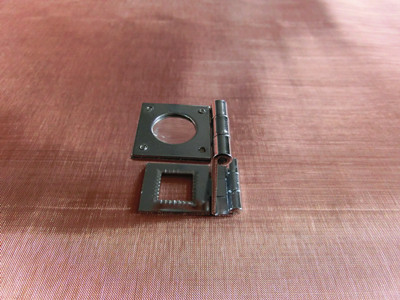

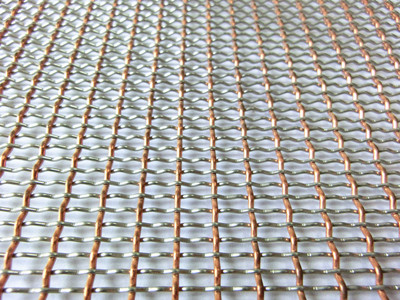

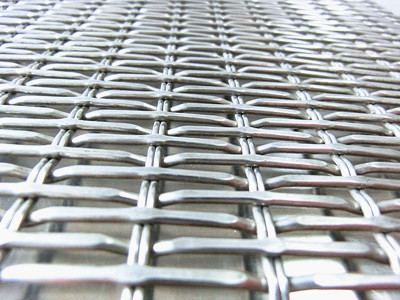

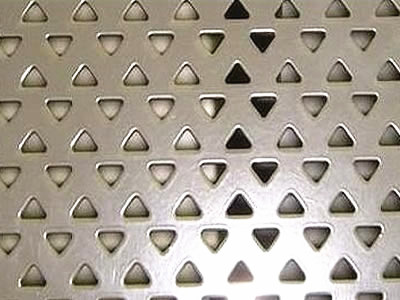

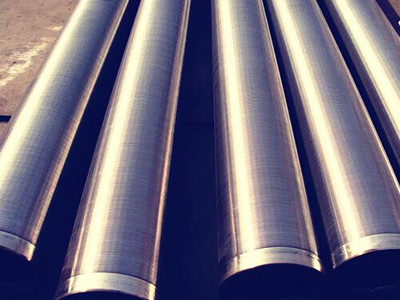

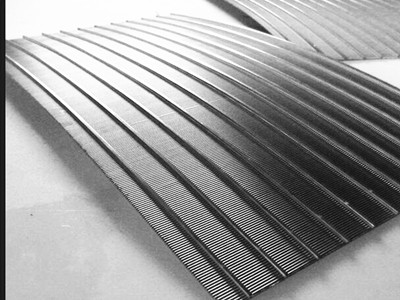

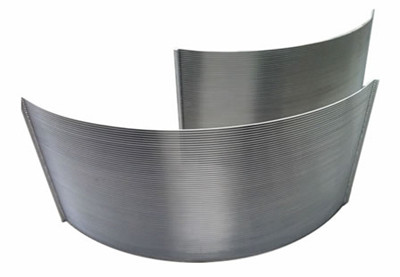

Wedge wire coanda hydro intake screen panel is manufactured by wrapping and welding vee type profile wires cylindrically around support rods, then be made into panel screen through cutting and radian processing.

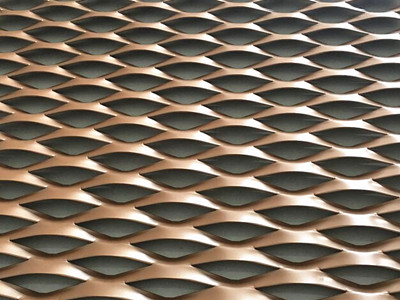

Coanda screen is an overflow intake, where the water runs over a weir and then through a fine-mesh screen and is normally used on small hydro projects. The Coanda screen is bent so that it is self-cleaning and can be built with a small gap width of 0.5-6 mm.

Benefits

A reliable supply of screened water which increases hydro plant operating time, output and efficiency

Self-cleaning properties result in a largely maintenance free operation saving time and associated costs

Slot gap sizes can be specified to screen debris from diameters as fine as 0.2mm up to a width of 2mm

No mechanical moving parts eliminates the need for costly maintenance and a power supply

Coanda Gap’s modular construction ensures ease of assembly

Highly resilient screen construction is resistant to abrasive material and corrosion

Trusted in fisheries conservation areas not to cause harm to fish stocks